Colorado state senators introduced the bill, End-of-Life Management of Electric Vehicle (EV) Batteries, as one of their top 5 priorities, signaling commitment to a lower-impact, circular EV supply chain.

Colorado is a leader in shifting to low-emissions vehicles. Thousands of EVs are already on the roads, and more are expected over the next decade. In the third quarter of 2025, Colorado led the nation, with EVs representing 27.3% of new vehicle sales. Lawmakers are now looking to establish robust battery recycling policies to ensure a sustainable transition to electric transportation. This includes making producers (typically automakers) responsible for ensuring batteries are safely recycled, setting recycling standards to reduce pollution and increase mineral recovery, increasing industry transparency through reporting, and implementing workforce safety education.

Some top benefits of the recycling policy include:

- Lowering the impact and reliance on newly mined minerals. By 2050, the United States could meet more than half of its demand for cobalt, lithium, and nickel for EV battery production via battery recycling, helping build a more secure and sustainable supply chain.

- Decreasing the risk of fire due to mismanaged retired batteries. Defining a party responsible for recycling reduces the risk of improper storage or dumping that can lead to fires, especially if batteries are damaged. In instances where batteries are involved in a fire incident, the costs are borne by taxpayers through costs covered by the fire department or local government. The cost of unmanaged batteries may also fall on entities that end up with them, such as municipalities or waste disposal companies.

- Regulating the market for retired EV batteries may lower the overall cost of electrification while capturing more value from the batteries. More efficient collection with strategically located facilities could reduce battery collection costs. In addition, increasing the supply of minerals through recycling may help stabilize mineral prices in the long run.

New Jersey was the first state in the United States to pass an EV recycling policy, but it does not clearly delineate responsibility for battery management, establish comprehensive reporting, or include recycling process requirements needed to make it effective. Colorado could be the first state to ensure the proper reuse and recycling of retired EV batteries. But making automakers responsible for ensuring EV batteries are recycled through extended producer responsibility (EPR) isn’t a new approach. China created an EPR and other recycling requirements in 2016, Korea in 2019, India in 2022, and the European Union in 2023.

What does the End-of-Life Management of Electric Vehicle Batteries Bill (SB 003) do?

Makes automakers responsible for the proper reuse, repurposing, and recycling of unwanted batteries

Senate Bill 003 allows the reuse and recycling market to continue operating as is for most batteries but also sets up a backstop to ensure the remaining batteries don’t slip through the cracks. Most retired EV batteries are valuable for reuse in other applications or for recycling and mineral recovery. However, some used batteries are more costly to transport and recycle. Batteries that have been damaged, for instance, must be handled with special precautions. This leads to higher collection and recycling costs, as well as an increased risk of battery mishandling and potential battery fires.

One important benefit of Senate Bill 003 is that it would ensure all EV batteries are collected and recycled safely, reducing the risk posed by the mismanagement of unwanted EV batteries. It would do so, in part, by assigning responsibility for recycling unwanted EV batteries to the automaker.

Creates recycler qualification standards to minimize pollution and ensure mineral recovery

Senate Bill 003 creates a Qualified Battery Recycler requirement to ensure these batteries are recycled using a process that prioritizes high mineral recovery and low pollution. The bill prohibits smelting as a recycling method for EV batteries. This is due to the technology’s lack of lithium and aluminum recovery, high energy demand, and high emissions. Smelting is done by placing the battery module or cell directly into the furnace. The battery is first heated to 350-600* C to burn off the electrolyte and then heated around 1200-1450* C to melt the metals into an alloy. Newer technologies, such as those that involve shredding, heat treatment at lower temperatures that don’t liquify metals, and then hydrometallurgical refining, show higher mineral recovery and lower environmental impacts.

The bill tasks the Colorado Department of Public Health and Environment with setting additional requirements that can evolve with the technology. This includes minimum mineral recovery rates, which will help ensure that, despite mineral price fluctuations, minerals are recovered and used to offset demand for newly mined minerals.

Increases industry reporting and safety training

Senate Bill 003 will increase industry transparency regarding end-of-life processing and battery characteristics and will also expand safety training procedures. For the regulation to be effective, industry reporting on the batteries collected, reused, repurposed, and recycled, and the mineral recovery rates used, is essential to confirm compliance.

The bill will improve the efficiency and safety of end-of-life processing by requiring battery labeling and access to battery health information. The battery label will provide crucial information about battery chemistry, size, and who to contact for end-of-life management. Battery health refers to the battery’s capacity and incidents of overheating, overcharging, or other faults. It is important that battery health be accessible to those handling the battery at retirement because it is a key determinant in deciding whether the battery should be reused, repurposed, or sent directly to recycling. Lastly, as part of the battery management plan, automakers will develop safety plan procedures to reduce the risk of fires throughout end-of-life processing.

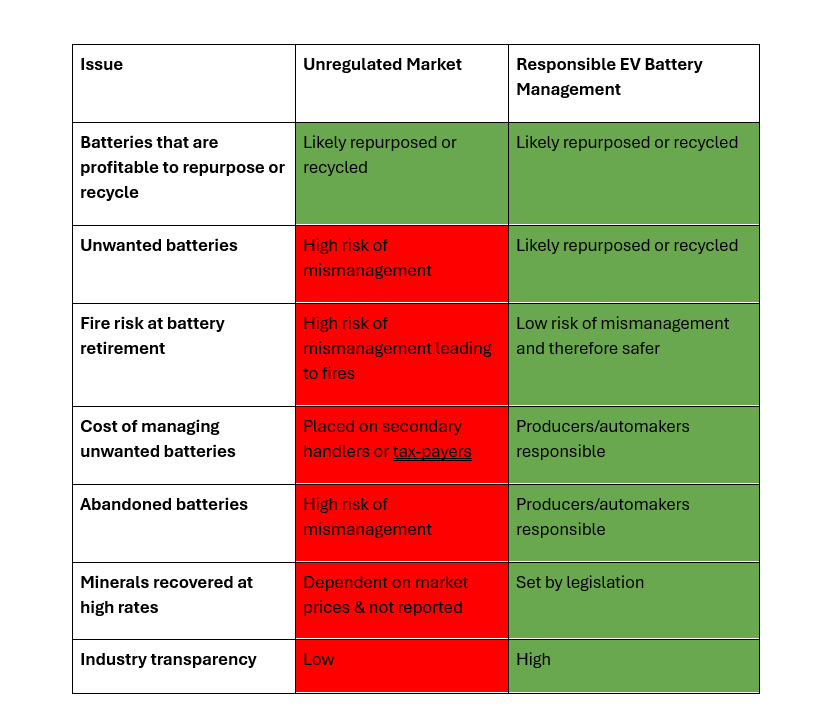

Creating Responsible EV Battery Management in Colorado

Below are the various components of the EV end-of-life landscape today. This table shows how they are handled now versus how they would be treated under the proposed legislation.

This policy is timely

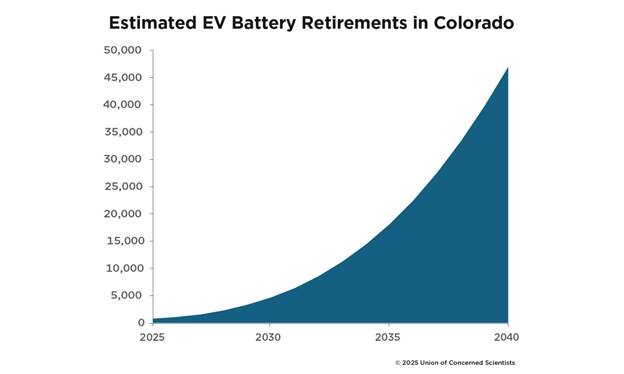

As a leader in EV adoption, Colorado will see increasing retirements in 2030 and onwards. The proposed Battery recycling requirements would take effect as these retirements ramp up to prevent mismanagement, as shown in the figure below. The experience with consumer electronics shows the importance of implementing a robust recycling policy before there is significant growth in batteries reaching the end of their life.

Assuming EVs reach about 80 percent of new vehicle sales in Colorado by 2032 (estimated to be about 182k vehicles), the number of batteries reaching the end of their life cycle will soar. (Source: ERM, The Benefits of the Colorado Clean Car Standard, May 2023.)

Consumer electronic batteries tell a cautionary tale about the need to get recycling right early. Battery fires from improperly disposed of small consumer electronics have cost the public millions of dollars and resulted in serious injuries. Regulations weren’t in place soon enough to address this hazard. We should learn from this failure and get ahead of the mass retirement of EVs by ensuring regulations are in place to enable safe, efficient reuse and recycling. Lead-acid batteries also tell a tale of what happens when we don’t get recycling right from the start. Lead-acid battery smelting has resulted in multiple public health disasters here in the US and around the world.

As we electrify our transportation system, it is essential that we reduce the environmental and social impacts of mineral demand while creating a resilient supply chain with low mineral prices. This Colorado legislation is well poised to be a nation leading example of how to do that, which other states around the country can follow.