The atrocities of unregulated lead-acid battery recycling across Africa were recently investigated in a New York Times article. This account brought due attention to a pollution problem that has also resulted in a public health disaster here in the United States. Steps should be taken to clean up this industry, and lessons from this failure can help ensure better outcomes in other essential efforts, such as lithium-ion battery recycling.

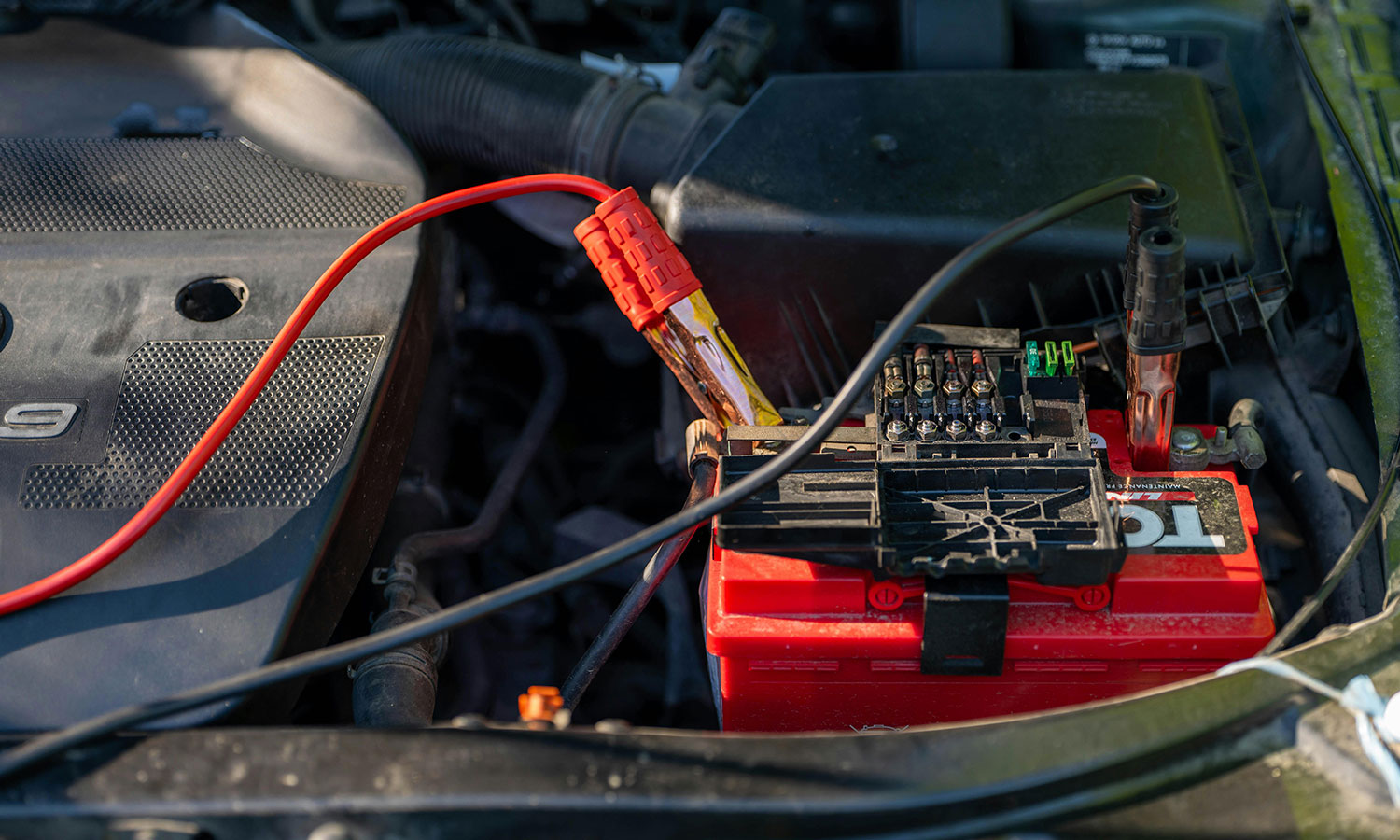

Nearly every gasoline and diesel vehicle sold has a lead-acid starter battery, and most vehicles will require several replacement batteries during their useful life. The mining of lead results in ecological and public health harms, and its recovery through recycling could create a lower-impact source. Unfortunately, due to improper regulations and lax enforcement of emissions standards at recycling facilities, the smelting process has often poisoned workers and surrounding communities.

The effects of lead poisoning are vast and most shockingly include developmental delays in children, including behavioral problems and reduced IQ. According to the CDC, there is no safe level of lead exposure for children.

While the recycling rates for lead-acid batteries are high, the process has gone underregulated in the United States, with smokestacks contaminating the surrounding air, soil, and water with lead that is eventually ingested by community members. Exide Technologies, a lead-acid recycler in California, was polluting for decades and is now an EPA superfund site.

Although efforts to enforce regulations in the United States have ramped up and cleanup is underway at some sites, many lead-acid batteries from the United States are exported to the Global South, where companies continue to cause harmful public health disasters, and US automotive companies subsequently purchase the recycled lead.

There is no US policy that requires the recycling of lead-acid batteries to minimize pollution, or that bans the export of this hazardous waste. There is also no tracking or reporting of where lead is being sourced or where retired batteries are sent. Tracking and reporting are two essential aspects of the circularity process. Increased transparency, in particular, can help consumers identify companies that are acting responsibly and encourage companies to do better.

Lead-acid batteries use a completely different chemistry from the lithium-ion batteries I typically focus on, which power electric vehicles. They contain different minerals and have different recycling processes and risks, but we would be remiss to dismiss the lessons learned from the public safety disaster of the lead-acid battery industry. We have an opportunity to do better with lithium-ion battery recycling. We can create a lower impact source that that reduces the need for newly mined minerals. But to do so, policies and regulations limiting the process’s impacts, regardless of where recycling occurs, are necessary.

Lessons learned

The recycling process matters

A closed-loop economy is not a success story unless the recycling process minimizes harm. Lead-acid batteries are recycled at a 99% rate, driven by the toxicity of the contained materials and a consumer buyback program (core charge). The failure lies in the recycling process. The process emits harmful lead when there aren’t proper pollution controls, and the regulations do not specify pollution controls or maximum pollution limits for lead batteries recycled outside the country. Looking ahead to lithium-ion battery recycling, we need to ensure that the recycling is done using a low-impact process with proper safeguards.

Stop the exportation of waste and pollution

The account of lead-acid battery recycling in Africa is a prime example of the harmful impacts of exporting waste for processing in countries with lower environmental standards. This is also true for other products such as plastics and electronics. The products generated by the US need to be recycled with proper emission controls and regulatory enforcement, to ensure this exportation of pollution doesn’t continue.

Traceability and reporting— corporate accountability

If a policy requires safe recycling, tracking and reporting are necessary to ensure compliance. Even without policy requirements, establishing transparency norms in the supply chain through reputable certifications can incentivize consumer-facing companies to source more ethically.

To date, the European Union has adopted traceability standards and transparency requirements. These extend to all products, and as fossil-fuel and lead-acid batteries phase out of the transportation system, they will also be employed in the clean energy economy.

As the United States transitions away from a fossil-fuel-based transportation system that uses lead-acid batteries, we must ensure that lessons learned are applied to a lithium-ion-based electrified transportation system. The lithium-ion batteries from our electric vehicles, electric buses, and electric bikes can all be recycled to provide a lower impact source of minerals—and should also be done at a high rate. While the recycling process and risks of lithium-ion batteries differ from those of lead-acid, we must ensure that no corners are cut and that the process uses proper pollution controls.