Recent investments in the US battery and Electric Vehicle (EV) manufacturing industry are key to establishing a robust supply chain and supporting job growth. Billions of dollars of investments have been driven by a powerful combination of (1) forward looking policies like state and federal vehicle standards, (2) incentives designed to kickstart a domestic battery industry, (3) automaker recognition that the future of the auto industry is electric, and (4) consumer demand for EVs.

While the rest of the world continues supporting their zero-emission commitments and races to be part of the EV economy, the Trump Administration and the 119th Congress are dismantling US industry support at nearly every turn.

Two weeks ago, Congress took the unprecedented step of revoking the authority of states to enforce standards accelerating the deployment of cleaner diesel trucks and electric passenger cars and heavy-duty trucks—a right that states have exercised for over 50 years to reduce vehicle pollution. Now, Congress and the Trump administration are attempting to use the Budget Reconciliation Bill to roll back EV manufacturing and consumers incentives, undo federal passenger vehicle fuel economy and emission standards, and add an excessive $250 annual fee on to EVs that is two-to-three times greater the taxes paid by the average gasoline driver.

These actions are not only a major setback to the deployment of EVs in the United States, but a major blow to the country’s nascent EV battery manufacturing supply.

US supply chain investments and job growth

Investment in the US EV supply chain is a smart move for creating jobs, building technology leadership in a growing industry, and lowering costs. You don’t have to look too hard to see that auto executives know EVs are the future. Even in the US, which lags behind other nations in EV adoption, 1 in 10 new vehicle sales are electric.

One critical element to success is building a robust EV supply chain here in the US. There was a flurry of supply chain investments supported by the Biden Administration and the 117th Congress, following the passage of the Bipartisan Infrastructure Law (BIL) and the Inflation Reduction Act (IRA).

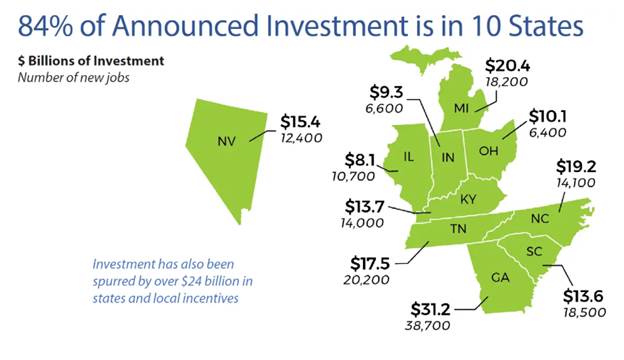

Over the past decade, approximately $198 billion in announced investments have been made in the manufacturing of batteries and electric vehicles (EVs) in the US, with the potential to create around 195,000 new jobs. Over 80% of these investments were announced after the passing of the BIL in 2022, thanks to the grants, tax credits, and subsidized loans. These policies are responsible for spurring the creation of a more reliable battery supply chain right here in the US. Notably, the states with the highest investments include Georgia, Michigan, North Carolina, Tennessee, and Nevada.

Figure and calculations by EDF

Investments are being made throughout the supply chain. If we look at lithium extraction, a mineral in all lithium-ion batteries, we see the US is forecasted to be a top lithium producer in 2030 due to increased mining expansion. The Argonne National Lab found that in 2022, Australia, Chile, and China were top producers, but in 2030, the US, Argentina, and Australia will likely rise to the top. Midstream battery production was a key target of funding by the Biden Administration and the 117th Congress. This involves manufacturing battery inputs, such as cathodes, anodes, separators, electrolytes, and cells. The Argonne National Lab reported that as of 2024, there were announcements for 79 electrode and cell manufacturing facilities and 63 facilities for battery-grade components manufacturing. Lastly, the US is also rapidly expanding the production of EVs and batteries. A 2024 study by EDF found that in 2028, EV manufacturing facilities would be capable of producing 4.7 million new EVs each year, and by 2024, there were announcements that point to the yearly manufacturing capacity of 1,083 gigawatt hours of EV batteries.

The jobs associated with these investments will also stimulate local economies. A recent report by Atlas Public Policy found that as of September 2024, 31% of the jobs announced were in census tracts deemed as Justice40 disadvantaged communities, meaning they experience high environmental and socio-economic burdens. In addition, they found that 12% are in communities that have experienced economic hardships due to the decline in the fossil fuel industry. It was estimated that over 800,000 additional jobs could be created through indirect employment – the result of increased spending in communities.

But the Trump Administration and the 119th Congress are attempting to slash many of these incentives that support this growing manufacturing base, including the New Clean Vehicle tax credit (30D), the Alternative Fuel Vehicle Refueling Property Credit (30C), and the Advanced Manufacturing tax credit (45X).

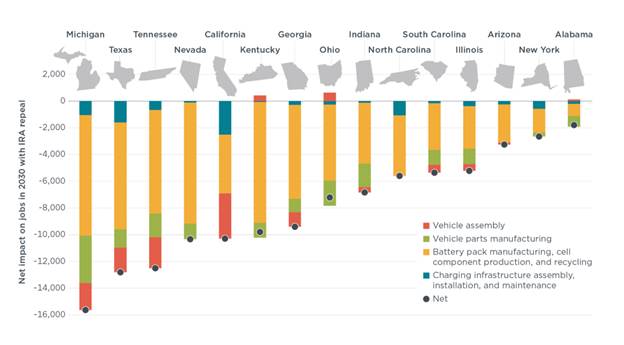

These policy shifts are pulling the floor out from under the US-based battery and electric vehicle (EV) manufacturing industry, and we are already seeing the cancellation of factory plans. It is clear that the reversal of these policies, tax credits, and grants, will slow the transition to EVs and is already hurting the US manufacturing base. An ICCT study estimates that repealing the IRA tax credits could result in a loss of 130,000 direct and 310,000 indirect US jobs by 2030. Most of these jobs are located in the Midwest and southern states where the manufacturing base is being established.

The net impact on jobs in 2030 if the IRA is repealed. Figure by ICCT.

We can still save the EV tax credit

This big push towards US EV manufacturing competitiveness was backed by strong demand-side policies that are at risk. The New Clean Vehicle tax credit (30D) included in the IRA reduces the cost of EVs up to $7,500, making them more affordable for middle income households. The tax credit is tied to domestic mineral sourcing and battery production restrictions, thereby designed to incentivize automakers to bring manufacturing to the US and diversify material sourcing to countries with trade agreements, sometimes referred to as “friendshoring”. Unfortunately, this tax credit is slated for elimination in the bill passed by the House in May, therefore creating more market uncertainty for the battery and EV industry. The current proposal eliminates it for most EVs in 2026 and the credit would go away completely by 2027. The Used Clean Vehicle tax credit (25E) is eliminated entirely, reducing accessibility for lower income households looking to switch to electric.

In addition, long-term industry-wide vehicle pollution standards play a crucial role, providing automakers with more certainty and direction for their R&D investments and enabling companies to compete on a level playing field. The EPA vehicle standards reduce global warming pollution, soot, and smog forming pollution. They incentivize manufacturers to increase the availability of clean vehicles that meet drivers needs. While this has been proven to be an effective approach to cleaning our air, it is now on the chopping block. As noted earlier, Congress has already moved to block states from implementing standards to bring more electric vehicles to dealers’ lots while the House has included provisions in the budget reconciliation bill to undermine federal fuel economy and emission standards.

These drastic policy changes, along with constantly changing tariff policies, are already hurting battery manufacturing investments. We are seeing stalled U.S. manufacturing investments, which, if they continue, could halt job production, harm our competitiveness in the global market, compromise supply chain security, and slow decarbonization.

However, the House changes are not baked into law—yet. The reconciliation bill is currently being considered in the Senate and several Senators have expressed an interest in tweaking tax provisions in the House bill. Until both chambers approve the same text there’s a chance cooler heads can prevail. President Trump wants the bill on his desk by Independence Day. Will the future of EV manufacturing go out with a bang? Or will drivers maintain freedom to choose the clean vehicle that best fits their needs? Your member of Congress needs to hear from you as soon as possible before these changes are baked in.

The US needs the EV tax credit to support our battery manufacturing investments

To continue creating a resilient and competitive US-based battery and EV industry, we need to support a policy environment of certainty. There have been three steadying strategies to building the US battery economy – invest in US manufacturing, amplify demand signals, and create strong and diversified partnerships with producing countries. The recent rollback of promised government funding and the current threat to the EV tax credits add to the environment of uncertainty that will hurt the US manufacturing base.

There’s no way around it – slashing incentives to build a US EV supply chain is a major blow at a critical moment. The US battery manufacturing industry is in a growth stage and relies on continued strong EV demand. The combination of demand and supply-side policies is the strategy that provides the best chance of successfully creating a resilient and competitive battery supply chain so that the US automotive companies lead in the global car market and American workers can build the cars of the 21st century.

Let your Senator know that the EV tax credits are not only important for cleaning our air, but also for the future of EV manufacturing here in the United States.